Factory Evaluation Sheet Ensuring Quality, Compliance & Capability

At Trend Bridge BD, our Factory Evaluation Sheet is a comprehensive assessment tool designed to ensure that every manufacturer we work with meets the highest standards of performance, quality, and compliance. This document serves as a critical checkpoint for our sourcing team, helping us make informed decisions before onboarding any new factory partner.

Our Factory Evaluation Sheet gathers in-depth information in key areas, including:

What We Assess

Manufacturing capabilities & equipment

Workforce skills and training programs

Quality control systems and procedures

Production capacity and scalability

Social compliance & working conditions

Health, safety, and environmental compliance

Past performance and reputation in the industry

Purpose and Scope

The goal of our evaluation is to ensure that the selected factory is capable of:

-

Meeting product quality expectations

-

Complying with international labor, safety, and environmental standards

-

Delivering consistent performance and timely production

Meeting product quality expectations

Complying with international labor, safety, and environmental standards

Delivering consistent performance and timely production

Product Specification Sheet Defining Every Detail with Precision

What is a Product Specification Sheet?

At Trend Bridge BD, our Product Specification Sheet is a detailed, single-page business document that outlines a product’s core features, construction details, and functional requirements. It serves as a critical reference point for design, development, and manufacturing teams—clearly defining the what, how, and why of each product we produce.

Why It Matters

This comprehensive sheet includes every important aspect of the product, from visual design and technical specifications to materials, dimensions, tolerance levels, functional requirements, and packaging guidelines.

It ensures that:

- All stakeholders are aligned on product expectations

Production is executed with minimal error or deviation

Quality standards are upheld consistently

Timelines are maintained by reducing rework and miscommunication

Our Factory Evaluation Sheet gathers in-depth information in key areas, including:

Key Components We Cover

- Product Design & CAD References

Materials & Finishes

Size, Fit & Tolerances

Functional Specifications

Testing Requirements

Labeling & Packaging Details

Compliance Notes (if applicable)

Our Product Specification Sheet is the guiding star throughout the entire product lifecycle—supporting transparency, traceability, and flawless execution from concept to delivery.

Cost Saving Analysis Maximizing Value Without Compromising Quality

Cost Saving Analysis Maximizing Value Without Compromising Quality At Trend Bridge BD, our Cost Saving Analysis is a strategic evaluation of the entire procurement and production process, aimed at identifying opportunities to reduce costs while maintaining—or even enhancing—the quality and performance of goods and services. Our Approach Our expert team conducts a thorough review of: Supplier pricing structures Material costs and sourcing alternatives Logistics and transportation expenses Operational processes and production efficiencies Objective The goal is to uncover savings potential across the supply chain—without compromising on compliance, delivery timelines, or product standards. Every recommendation is based on data-driven insights, industry benchmarks, and our experience across global sourcing operations. By implementing our cost-saving strategies, clients benefit from: Reduced overall procurement expenses Improved production efficiency Sustainable sourcing solutions Enhanced profitability Our Cost-Cutting Analysis goes beyond simply reducing expenses—it focuses on making strategic decisions that drive long-term value and optimize current spending. At Trend Bridge BD, we recognize that true cost efficiency comes from a blend of tactical savings and forward-thinking planning. We embrace continuous innovation and remain agile in response to shifting market dynamics and evolving internal needs. By emphasizing holistic cost management strategies, we don’t just aim to reduce costs—we strive to enhance operational resilience and fuel sustainable growth. This proactive approach enables us to thrive in the competitive global market, delivering smarter sourcing solutions for our clients. Implementing Cost-Saving Measures At Trend Bridge BD, we implement structured and sustainable cost-saving initiatives that go beyond surface-level reductions. Our approach is grounded in operational excellence and continuous optimization.

- Conduct Regular Audits We routinely audit sourcing procedures, supplier contracts, and logistics operations to identify inefficiencies, detect overcharges, and uncover hidden cost-saving opportunities. These audits ensure alignment with market benchmarks and operational transparency.

- Employee Training Our team receives ongoing training on cost-effective practices, sustainable sourcing, and emerging market trends. Well-informed staff make smarter, faster decisions—minimizing costly errors and increasing overall productivity.

- Continuous Improvement Culture We foster a culture of continuous improvement, where feedback is encouraged, and every process is evaluated regularly for efficiency. This enables us to identify bottlenecks, streamline operations, and integrate smarter, leaner practices across all departments. These proactive measures help us deliver consistent value to our clients while strengthening long-term competitiveness in an evolving global market.

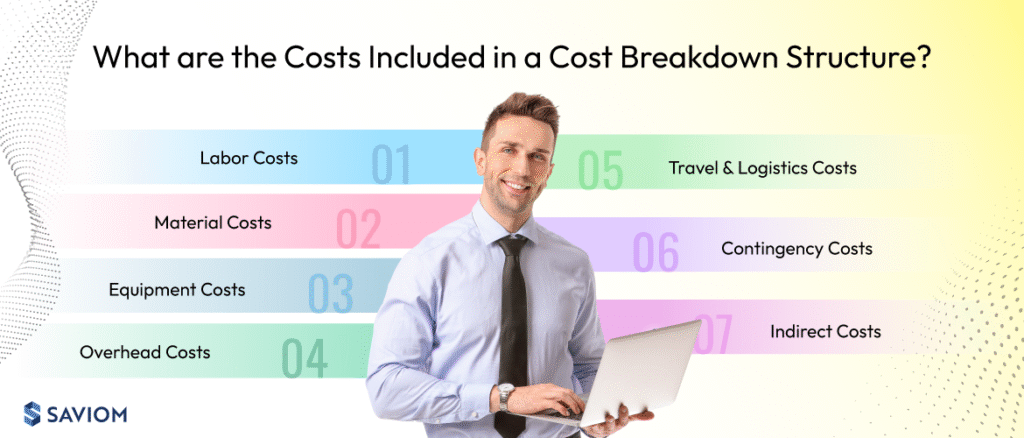

Cost Breakdown Sheet Transparency. Strategy. Smarter Decisions.

At Trend Bridge BD, the Cost Breakdown Sheet is a vital tool that delivers a transparent and detailed view of all expenses involved in the manufacturing and distribution of a product. This clarity strengthens trust between vendors and buyers, supports informed decision-making, and enables better budget and negotiation management.

Key Components of Our Cost Breakdown Sheet

We analyze and document the full spectrum of production and delivery costs, including:

- Raw Materials – Base input materials and sourcing

Labor – Skilled and unskilled workforce contributions

Manufacturing Overheads – Energy, depreciation, maintenance, etc.

Packaging – Primary and secondary packaging costs

Quality Control – Inspection and testing costs

Logistics – Freight, handling, and delivery

Profit Margin – Reasonable markup to ensure business viability

Why Cost Breakdown is Important

Understand True Cost Structure – Gain full visibility into how prices are formed.

Enhance Negotiation Leverage – Make fact-based discussions with suppliers.

Ensure Fair & Competitive Pricing – Maintain market alignment and avoid overpayment.

Mitigate Risks – Identify and manage cost-related supply chain risks early.

Outcome

Only factories that meet our strict criteria are approved to join our supply chain network. This process minimizes production risks and ensures that our clients receive products from ethically compliant, technically capable, and quality-driven manufacturers. To ensure the highest standards and consistent quality across our supply chain, Trend Bridge BD relies on a detailed Factory Assessment Sheet as a vital tool. Through comprehensive evaluations, we ensure that we collaborate only with reliable, capable manufacturers who not only deliver superior product quality but also strictly adhere to ethical practices and legal compliance. This proactive approach helps us maintain excellence and accountability throughout every stage of production.

A Nation of Strength & Productivity Bangladesh holds a powerful position in global production due to several key advantages:

- Vast Population & Skilled Manpower

With a large and skilled workforce, Bangladesh offers an unmatched ability to scale production efficiently and cost-effectively. - Creativity Rooted in Tradition

Bangladesh have long been known for their creativity and craftsmanship. From ancient trade routes to modern markets, Bangladesh has consistently impressed the world with its high-quality, innovative products. - Legacy of Innovation

While today’s world relies heavily on advanced technology, many modern production methodologies find their roots in Bangladesh ingenuity. This legacy continues, as the current generation seamlessly blends tradition with cutting-edge techniques.

Defects Classification Sheet Ensuring Consistent Quality Through Standardized Evaluation

At Trend Bridge BD, maintaining product quality is at the core of our sourcing philosophy. Our Defects Classification Sheet is a vital tool in ensuring rigorous quality control, fostering strong supplier relationships, and maintaining compliance with international product standards. This sheet allows our Quality Assurance (QA) team to efficiently identify, classify, report, and resolve product defects throughout the production and inspection process.

Defect Categories

Defects are categorized based on their severity and impact on the product’s function, appearance, or safety:

Critical Defects These defects render the product unsafe or non-functional. Products with critical defects are rejected outright.

Major Defects These affect usability, performance, or appearance in a way that would cause the customer to return or reject the product.

Minor Defects These are cosmetic or slight imperfections that do not significantly affect the function or value of the product.

Key Components of Our Defects Classification Sheet

Defects are categorized based on their severity and impact on the product’s function, appearance, or safety:

List of Specific Defects Each defect category includes tailored defect types relevant to the specific product line (e.g., stitching defects in garments, material discoloration, packaging flaws).

Defect Codes Every defect is assigned a unique identifier for streamlined reporting, tracking, and analytics.

Acceptable Quality Levels (AQL)

We define strict AQL standards based on product type, usage, and customer requirements to determine permissible defect thresholds.Defined Inspection Standards

Detailed protocols outline how each defect type should be inspected, ensuring consistency across inspections.

- Digital Reporting Mechanism

We utilize standardized digital forms or QA platforms to report and escalate findings, ensuring transparency and traceability. Staff Training & Awareness

Our QA and procurement teams undergo continuous training on defect identification, classification protocols, and corrective actions.Ongoing Review and Updates

The Defects Classification Sheet is a living document—regularly reviewed and revised to align with:- Evolving industry standards

- Production technique changes

- Lessons learned from inspections

By implementing a structured and standardized defect classification system, Trend Bridge BD empowers teams to maintain consistency in product quality, reduce returns, and boost customer satisfaction.

Inspection Reports

Ensuring Quality and Compliance at Every Stage

At Trend Bridge BD, inspection reports are critical components of our quality control and assurance framework. These reports are prepared following comprehensive inspections conducted at our manufacturers’ or suppliers’ facilities to ensure that all products meet the buyer’s specifications and global industry standards.

Types of Inspections Conducted

- During Production Inspection (DUPRO): Performed at various stages of production to assess semi-finished or nearly completed goods. This helps ensure production consistency, timeline adherence, and early detection of issues.

Pre-Production Inspection (PPI): Conducted before manufacturing begins, this inspection verifies raw materials, components, and factory readiness to ensure that initial inputs meet quality requirements.

Pre-Shipment Inspection (PSI): Conducted after a substantial portion (typically 80-100%) of goods are completed. It checks that final products meet contract specifications and quality expectations before shipping approval.

Value of Inspection Reporting at Trend Bridge BD

Transparency: Detailed reports provide visibility into each inspection stage.

Data-Driven Decisions: Reports help clients and internal teams make better sourcing and production decisions.

Supplier Accountability: Reporting holds suppliers accountable and reinforces a culture of quality.

Proper handling and documentation of inspection reports are central to how Trend Bridge BD ensures product integrity, maintains buyer trust, and strengthens supplier relationships. Effective inspections reduce risk, drive higher quality standards, and ultimately boost customer satisfaction.

Trend Bridge BD is a leading sourcing and service provider company, recognized as one of the best buying houses in Bangladesh. At Trend Bridge BD, we focus primarily on the quality of products, along with offering competitive pricing.

Bangladesh Office:

KA-50/D, South Badda, Dhaka-1212, Bangladesh.

Phone: +8801921494972

E-mail: ceo@trendbridgebd.com

The Netherlands Office:

Street name: Roer

House number: 8

Post Code: 1319CM

City: Almere

The Netherlands

Phone: +31624884440

E-mail: info.nl@trendbridge.com

© Copyright Trend Bridge BD

All rights reserved & Designed and Developed By Trend Bridge BD